Philippines Poultry Chicken Meat Processing Machines & Equipment

The pace of technological innovations is getting quicker and quicker. During the last several decades, big corporations have relinquished their market share to smaller sized business who are much more adaptable and agile to modern technological innovations. Clearly, this trend is definitely here to remain and absolutely no industry is going to be exempted by this evolution.

From an individual restaurant to big food catering companies or huge poultry (chicken, turkey, and duck) farms and poultry processing plants, our company specializes in helping automate your poultry processing systems with an emphasis on business ROI.

Food Pro Industries is truly a company that specializes in assisting the food processing industry change in transforming into the winner of tomorrow. With a focus on poultry (duck, chicken, and turkey), our ambition is to works with all players in the poultry sector adapt the latest technological innovations in poultry (chicken, duck and turkey) industry. We are aware of the usefulness of being relevant and harnessing cutting-edge technology to minimize the demand for human labour whilst improving output. We specialize in supporting customers utilize the most advanced poultry machines and equipment to remain in business and beat your rivals.

More than automated machines – We are equipping your business with a competitive edge to secure your future. Survive the technological disruptions today and emerge as the winners of tomorrow.

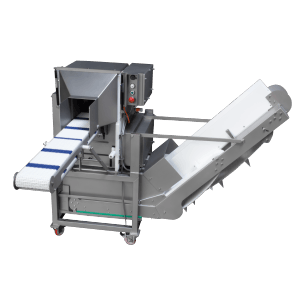

Steen Food Processing

Poultry Meat Processing Machines and Technologies

Not many companies in our industry can profess 50 years of expertise under their belt. We are pleased to announce that we are among them. In the 50 years, we have noticed first-hand how technologies disrupt the method we manage and operate businesses. We have also observed how fast evolving poultry meat processing can possibly be.

Poultry Chicken Processing Innovation

With over 50 years of expertise in mechanical engineering and its application in the food processing industry– specifically for poultry meat processing, our team develop the technical proficiency within this fast changing food processing niche. Our team are most probably the best in our selected field of work and our company believe if you partner with us for your requirements in poultry meat processing, our team will create great value to your company in regards to returns and operational efficiency

Typically, most of our clients who need poultry meat processing process chickens, turkeys and ducks. We have extensive knowledge in this field and as a matter of fact we presently have top of class poultry meat processing equipments that can perform a highly specialised activity in your food production processes that offer you with substantial return on investment from less dependence on manual labour and the increase output produced by our poultry processing machines.

Broiler Poultry Processing

Our range of broiler chicken cutting equipments can help you raise the return of broiler processing with minimal requirement for manual labour. Broiler processing plants along with their huge volume of processing requirement can make the most of poultry automation to increase their profit via raising output with much lower labour cost.

Broiler chickens (also known as Gallus gallus domesticus), or broilers, are a group of domesticated fowl reared and bred mainly for meat (chicken) production. Essentially, they are a hybrid of egg-laying chicken and a subspecies of the red junglefowl (Gallus gallus). Generally, broilers have white feathers and yellow-like skin. Commerical broilers get to slaughter-weight between 5 to 7 weeks of age although some slower growing breeds reach this weight at around 14 weeks.

Poultry Processing Machines

Our poultry skinning machines can extract the skin from chicken whole breasts, breast caps, split breast bone and whole legs of chickens. We can also skin turkey half breasts, turkey whole legs, and thighs. We also offer specialised stand-alone skinner capable of processing dry or wet chilled poultry chilled products at high speed in which the skin is removed in one single piece for maximum productivity

An additional accomplishment our poultry meat processing machines can achieve is the fillet splitter which eliminates the membrane of the butterfly fillet when producing single fillet of the poultry “butterfly”.

Broiler chickens (also known as Gallus gallus domesticus), or broilers, are a group of domesticated fowl raised and bred especially for meat (chicken) production. Basically, they are a hybrid of egg-laying chicken and a subspecies of the red junglefowl (Gallus gallus). Our poultry skinning equipments can remove the skin from chicken whole breasts, breast caps, split breast bone and whole legs of chickens. We also offer specialised stand-alone skinner capable of processing dry or wet chilled poultry chilled products at high speed where the skin is taken out in one single piece for maximum efficiency

Currently, our variety of poultry meat processing machines can support you in poultry skinning, poultry de-boning, mid-wing tulip processing, poultry spare-rib cutting and poultry fillet splitting.

Even when it comes to automating challenging tasks which include mid-wing tulip processing, our machines can still perform the task of removing one end of the wingette with the bone removed to create a nice looking “tulip”.

If you need to extract the poultry spare rib, our spare rib cutter can automatically separate two pieces of meat located on both sides of the bones with an output of 100 thighs per minute with only 2 machine operators.

Our turkey de-boning equipments also automatically debone turkey thighs, drumsticks, and prime wings at the performance of 35 pieces per minute through the operation of one machine operator.

With respect to de-boning (removal of poultry bones), we have specialised machines for turkeys and chickens where we can debone chicken thighs and drums with maximum yield Our chicken de-boning equipments centers the bone and then pushes it through a hole in a diaphragm where the chicken meat is removed off with the maximum yield.

Our company have also observed how swift evolving poultry meat processing can be.

Showing 1–12 of 15 results

-

De-boning machine ST850/628DTW8

-

Steen Automatic breast skinner high out feed ST650/H machine

-

Steen AUTOMATIC BREAST SKINNER LOW OUT FEED 650 Machine

-

Steen Automatic skinner long model ST600/K machine

-

Steen Automatic Skinner Long Model ST700/K Machine

-

Steen Automatic skinner short model ST700/K10 machine

-

Steen Chicken De-boning mid-wing chicken ST820 Machine

-

Steen De-boning + cartilage remover machine low capacity ST832 machine

-

Steen De-boning machine high capacity ST800 machine

-

Steen De-boning machine low capacity ST828 machine

-

Steen Fillet splitter ST350F Machine

-

Steen Pirzola + De-boning ST840 Machine & Equipment