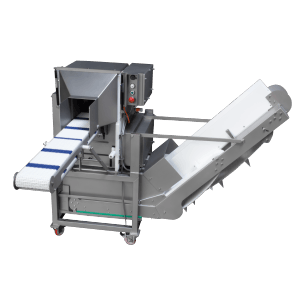

Steen Automatic skinner long model ST600/K machine

Steen Automatic skinner long model ST600/K machine

Product Description

Our poultry (chicken, turkey, duck) processing machines are ideal for poultry (chicken, duck and turkey) farms, poultry processing factories, poultry distributors, central kitchens that process chickens, ducks and turkeys, chains of food & beverage outlets that process turkeys, ducks and chickens. With automation in poultry processing, you reduce the need for manual labour and increase your output via our polutry processing equipment.

Dedicated to advance food processing automation modern technologies in the food industry, we are experts in automated fish/ poultry meat processing automation. Our machines are capable of fish scaling, fish skinning, eel processing, de-scaling, fin tail cutting for fish and poultry (chicken) skinning, chicken breast skinning, chicken de-boning. We serve all food producing players across the food supply chain who need to have top quality food processing automation equipments. The STEEN ST600KU skinning machine is capable of processing wet or dry chilled products at high speed. The skins are taken off in one piece for increased value.

The STEEN ST600KU skinning machine can be a dual lane fed machine which in some circumstances allows the processing of two different products at the same time. Can be used for skinning:

Chicken: thighs, drums, whole legs, fillets and breast caps

Turkey: thighs, drums, whole legs, halve fillets and breast caps.

Additional effort has been taken to integrate additional safety and hygiene functions. Our poultry processing machine is specifically baseded on special provisions to facilitate operation, decrease machine repair and maintenance and enhance the residual value with time for your investments.

Our Steen poultry processing machine symbolizes an industrial concept for skinning and deboning poultry (ducks, turkeys, chickens) in the most efficient way.

The STEEN Poultry processing machine is, because of our decades of expertise in mechanical engineering and development. We crafted an industrial technique for processing poultry in probably the most efficient way, adhering the stringent demands of the modern food processing industry (CE).

Additional information

| Operators | 1-2 |

|---|---|

| Speed | +/- 17 m/min |

| Working width | 460 mm |

| Voltage | 220-440V-50-60Hz |

| Capacity | 2,25 kW/3Ph |

| Controls | 24V |

| Length | 2.830 mm |

| Width | 711 mm |

| Height | 1.400 mm |

| Weight | 360 kg |

| Water Cons. | 8 I/min (Optional) |

| Air Cons. | / |